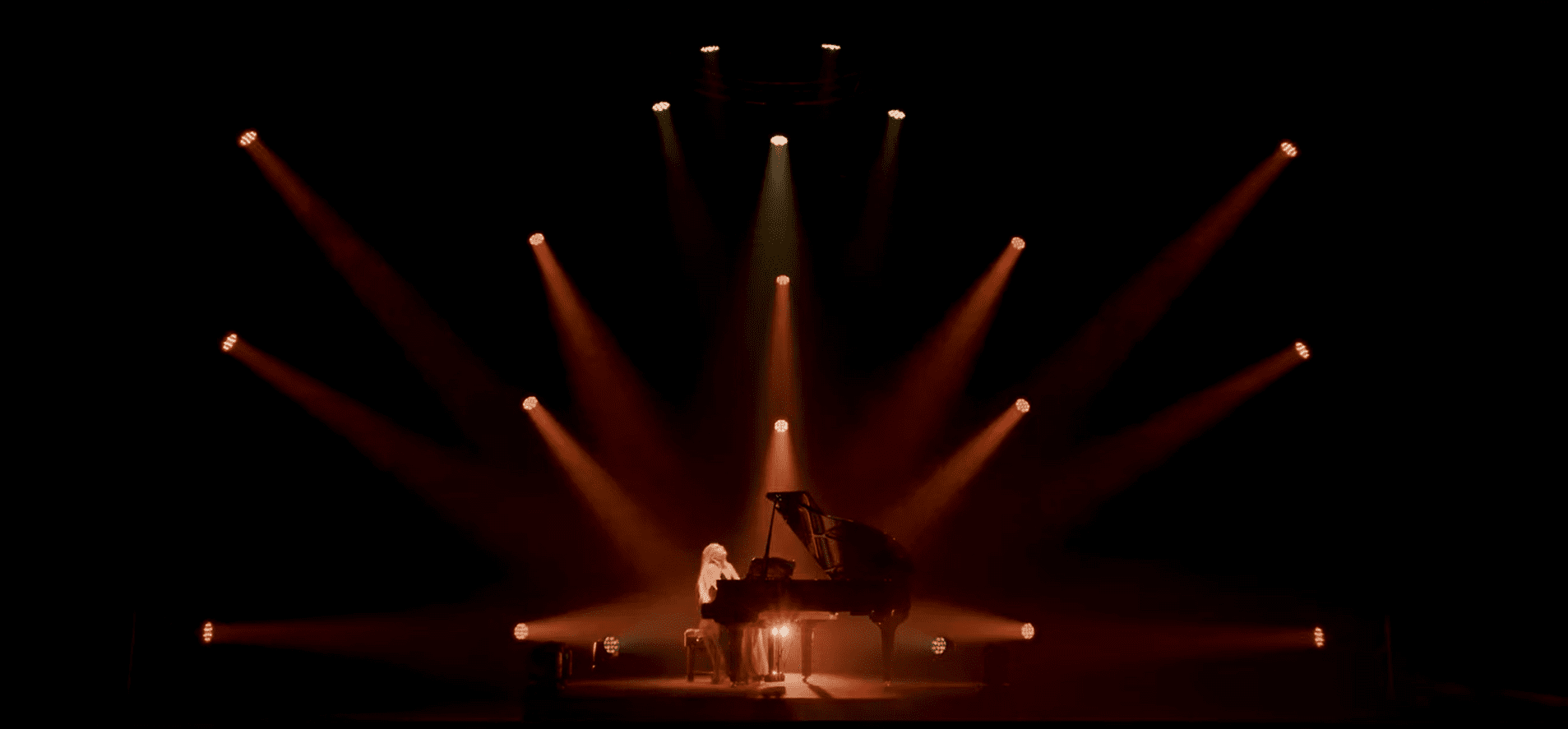

Today, professional stage lighting equipment is an integral part of various event productions. Whether we are talking about the production of a theater performance, music festivals, concerts, operas or ballets, stage lighting is an indispensable part of such events. As lighting technology developed in proportion to the technological achievements of mankind, intelligent or automated lighting equipment was also created. Exactly such equipment is the topic of today's blog.

1. Automated lighting fixtures

We find the term intelligent lighting in the division of lighting fixtures. This term refers to lighting that has automated or mechanical capabilities beyond that of traditional, stationary lighting. This is precisely why we call these lighting elements by various names such as; automated body lighting, intelligent lighting, moving lights, moving heads moving , and in slang, simply movers. The previously mentioned automated or mechanical abilities that allow automated lighting to precisely direct the controlled light beam to certain desired positions in the space. This is achieved through various possibilities of body movement, such as rotation, horizontal and vertical movement.

We can trace the history of intelligent lighting and the impact of new technologies on it from the very beginning of the 20th century. There are many patents for intelligent lighting that date back to 1906 , and with the development of electronics, lighting elements have also been developed. Automated lighting fixtures as we find them today were first developed in 1985 when Summa Technologies produced the first moving head using the DMX protocol. Until then, moving lights were using other communication protocols, such as the outdated DIN8, AMX, D54. The movement and other possibilities of the moving heads, which on some lighting elements can even be a 360-degree rotation, are controlled via the DMX Digital Multiplex protocol. The DMX signal enables the operator to program and control the lighting element or body. Through it, commands are issued in a simple way using the lighting control panel or programming applications, which we will discuss more about in the rest of the blog, through which we manage the automated lighting.

In order for a lighting fixture to be considered automated, it needs to have more than one DMX channel, and in addition to the dimmer, at least one more option is required, for example, movement. For example, an LED par lighting elements have three DMX channels, i.e. three colors (red, blue, green) that the operator can use separately. The development of technology has resulted in more advanced devices that we use today. They have various combinations of characteristics and some of them are:

- Horizontal movement of the lighting fixture (left-right)

- Vertical movement of the lighting fixture (up and down)

- Body rotation

- Dimer

- Gobo (static rings with gobo effect)

- Gobo rotation (alternating and rotating multiple rings with a gobo effect)

- Using a color ring

- CMY filter (filter ring with basic complementary colors – cyan, magenta and yellow)

- Prism rotation

- Shutter

- Interchange and rotation of the ring of effects

- Zoom and focus

- Iris

- Preprogrammed ignition or shutdown

2. Control of automated lighting fixtures

Automated lighting devices are controlled in various ways. Most lighting fixtures have a small screen on them where commands can be manually selected. Of course, this does not answer us during live application when we have a large number and various types of lighting fixtures. That is why the devices are most often connected to lighting control panels (lighting mixers) to which lighting operators send a signal and various commands through it. There are three main ways in which the control panel sends data to the lighting fixtures:

- Analog

- Dmx protocol

- Ethernet protocol

Automated lighting devices receive and process signals through the so-called servo stepper motors located inside each of them. Using the DMX protocol, through an insulated cable with XLR connectors (most often five-pin), the signal travels from the lighting desk to the lighting device, which then processes and implements the sent command. Servo motors enable various manipulations of the light beam. Whether we are talking about physically moving the beam of light (pan and tilt capabilities) or moving the light on the X and Y axis, servo motors are responsible for that.

Servo or stepper motors are also connected to the internal mechanical and optical parts of the automated lighting fixture, which allows for various ways of controlling the light beam. Rotation, movement, or the very speed of these possibilities naturally depends on the weight of the device. This is exactly why smaller, lighter lighting fixtures are used for fast movements.

Some of these internal mechanical and optical parts are:

Shutter (mechanical shutter) – allows changing the intensity of the light beam. There are various types with which we get a strobe effect with a high speed of opening and closing the aperture.

Gobo – it allows changing the shape of the light beam or projecting an image, and some lighting fixtures also have additional mechanical parts that allow the gobo to rotate to obtain a rotating light beam effect.

Prism– by rotating this element, we obtain the division of the light beam into several smaller beams.

Ring in colors – an alternating moving ring that contains filters in various colors that change the color of the light beam.

Automated moving lenses – enable the function of zooming and focusing the output light beam.

Iris – serves to change the size of the light beam.

3. Types of automated lighting fixtures

Today, there are various types of automated lighting devices that differ in their purpose, characteristics and width of the light beam. All automated lighting fixtures have been developed from three basic groups of Wash, Beam and Spot elements of professional lighting. Each one provides its own unique attributes such as stunning patterns, breathtaking colors and spectacular beams of light.

3.1. Wash

Automated Wash lighting fixtures deliver wide illumination, i.e. a wide beam of light. Their light output angle is over 50 degrees. For this very reason, they are used at closer distances. They are used to paint the scenography or as a counter light for performers. The main advantage of Wash is the ability to mix colors, which results in them melting. Today, due to their many possibilities, we mostly encounter LED Washes. They have been perfected so that it is possible to turn on, turn off and change the colors of each individual diode on the device. This enables pixel mapping, which is very popular today. Another of the main features of Wash automated lighting fixtures is the change in color temperature.

3.2. Spot

In contrast to the wide light beam of Wash lighting elements, Spot automated lighting fixtures are focused beams of light that are not wider than 45 degrees. This allows them to have a longer reach of the light beam than the Wash body. Their lenses enable zoom and focus, and this results in a sharp edge of the light beam. They have the option of using gobos that can be sharpened or blurred as needed with the help of zoom and focus. They can also use filters to change the color. They are used to apply various effects, as a front light for performers, as an accented counter light, for designing various textures, etc.

3.3. Beam

Beam automated lighting fixtures differ from the above ones mainly in that they have the smallest light beam exit angle. The beam angle of Beam lighting fixtures is just a little more than 0 to 1 degree, and this allows them to cover very distant points with a very strong light beam. Beam elements are the smallest of these three from the basic group, which enables them to move very quickly and also to install easily. The disadvantage of the device's small size and high lamp power is the inability to add CMY color filters. For this reason, the volume would actually burn the filter, so the Beam element uses glass rings with colors, which results in a small delay or cut between color changes. Just like Spot automated bodies and Beam devices, they have zoom, and the possibility of using gobos and prisms. They are mostly used as a light source for various effects, and they can change positions very quickly and are very agile. The application of Beam is multiple, we find them in various clubs and even on film sets.

3.4. Automated profiles

The automated profile has the same qualities and is used as a spotlight, but in order to differentiate them and have an additional function in the application, so-called knives are added to control the light beam. They actually serve as a frame that "cuts" the light beam into the desired shape. They are very often used in stage lighting, especially in the theater and on television.

Our recommendation: https://www.robe.cz/tx1-posiprofile

3.5. Hybrids

Automated lighting devices that are actually a combination of the previous three basic types of lighting fixtures are called hybrids. Most often, they have the ability to spread the light beam from 4 to 50 degrees. Manufacturers of professional lighting know that quality new lighting elements simply have to be innovative. It is precisely for this reason that we find various devices with the most diverse features on the market. That's how hybrids were born. They most often combine Beam/Spot or Wash/Beam options, but there are also lighting fixtures that combine all three basic types.

Our recommendation: https://www.robe.cz/megapointe

4. Possibilities of moving head lighting fixtures

As we have already mentioned, automated lighting fixtures have various features and various effects. From fast and slow movement to various mixing of colors, gobs, changing the intensity of the light beam and more. Below, we will describe some of them in more detail, as well as the light sources of automated lighting fixtures.

4.1. Sources of light

A powerful and highly efficient light source is an essential part of any automated lighting fixture. Since standard halogen lamps with tungsten filaments are very sensitive when moving, they are not suitable for the needs of movers. For this reason, automated lighting uses HMI lamps, i.e. lamps with an electric (Volta) arc.

In order to create a Volt arc, i.e. light, the device must contain a lot of additional parts such as voltage regulation, various insulations because such bulbs produce a lot of heat, a catadiopter that directs the light in the right light. In order to reduce the size itself and improve the ability to move, automated lighting fixtures today increasingly use LED light sources. One or more powerful LEDs are increasingly replacing classic arc lamps. Today, there are various types of LED light sources, and in the case of automated lighting fixtures, they are:

- White LED light source

- RGB LED – The diode delivers a light source in red, green, and blue colors, RGB LEDs combine these three colors to produce over 16 million shades of light. by combining them we get a white light source.

- More LEDs - i.e. more smaller light sources, with lower intensity (e.g. with Wash elements)

4.2. Dimmer – changes in the intensity of light

Dimming, dimmer, are well-known words in professional lighting and refer to the control of the intensity of the light beam coming out of a light fixture. Dimming the intensity of the light beam is necessary during most productions, whether we are talking about concerts, theater or television. Unlike the halogen bulbs that we use in everyday use and dim the light simply by turning the control, most automated lighting devices cannot change the intensity electrically. That is why mechanical methods such as Shutter Dimming are used to change the light intensity. For such a method, a mechanical mask is added to the automated light fixture, which mechanically reduces the output power, i.e. the intensity of the light beam, with the motor.

High-quality automated lighting fixtures use electromechanical modern dimmers. They control the amount of voltage in the circuit using thyristors, simple electronic circuits that turn on and off quickly, allowing the exact amount of current that is needed to flow through them. By doing so, they reduce the intensity of the light beam.

4.3. Gobo i prism

A gobo is an object placed inside or in front of a light source that controls the shape of the light beam. Even though they belong to old technology, they are still a very useful and popular lighting effect. Automated lighting fixtures usually already have built-in Gobos, i.e. one or more gobo rings that have the ability to rotate. There is also the option of replacing the gobo by simply changing the ring with new designs. The gobo is placed in the middle of the light source, its plate has various patterns through which the light beam is refracted, and thus we get various light effects or designs. That's why these rings are very popular in stage lighting. Lighting designers use them to get a variety of themes and decor for their events. Gobos are actually a very simple way to turn your lighting fixture into a magical machine that will fill your concert or event walls with various patterns. There is also the possibility of placing two gobo rings one over the other, which enables even more interesting and unique effects. The gobo is most often used with a focus option so that the design can be adapted to the background. There are many types of gobos from "old-fashioned" metal to glass and plastic. Today, plastic gobos used with LED light sources are increasingly popular. They can be in full color and a wide variety of patterns, which can even be personalized with some manufacturers.

Prisms, like gobos, are additional parts of automated lighting fixtures. They divide or refract the light beam into multiple beams. In automated lighting, different prisms are used that can divide the light beam into a very large number (even over 25 refractions). Of course, there are also prisms that can be rotated, which gives us even more amazing light effects.

4.4. Focus and zoom

Most automated lighting fixtures have focusing and zooming capabilities. This allows lighting designers to control the output light beam. Automated lighting fixtures have a whole set of various lenses that actually enable them to focus, change the sharpness of the beam and the ability to zoom, expand and shrinkage of light beam.

5. Conclusion

Automated lighting fixtures represent a key innovation in the world of stage lighting. Their ability to precisely direct the light beam to specific positions in space and various manipulations of lighting effects provide great creative freedom and improve the overall experience of experiencing stage events. Through the development of technology, automated lighting fixtures have become increasingly advanced and sophisticated, with capabilities such as horizontal and vertical movement, rotation, motorized use of gobos, prisms, color filters, zoom and focus, and many others.

Light management with the help of intelligent lighting fixtures brings new dimensions to stage lighting and enables the creation of spectacular visual effects. Their increasing popularity and use in various productions testify to their invaluable contribution to performing arts and events around the world. In the future, we can expect further development and innovation in the field of automated lighting, which will result in even more impressive and sophisticated stage experiences.

In our LAV Studio d.o.o. distribution, you can find various automated lighting fixtures of renowned world brands. Our company is dedicated to providing high-quality lighting equipment that meets the most demanding needs of the stage industry and our clients. Cooperation with the world's leading manufacturers of professional lighting fixtures allows us to provide a wide selection of high-quality products, which are known for their reliability, functionality and innovation. Our distribution network provides access to top professional lighting products with expert support to our clients in the entertainment industry, theater, concerts, television, events and other stage events. The LAV Studio offer includes a wide range of automated lighting fixtures, special lighting effects, control consoles and many other innovative products. Products from our distribution enable creativity and flexibility in achieving the desired stage effects, creating visually impressive experiences for your audience.

With our distribution network, clients can be sure to receive top quality professional lighting equipment backed by reliable service and technical support. Our expert team has many years of rich experience in the field of lighting and is always ready to provide advice and support in choosing the most suitable lighting solutions for the specific needs of each client.